Flexible Packaging

- Consistent and reliable print values

- Longer blade life versus steel

- Eliminate Roller scoring

- Safer working environment

- Increased profitability

Esterlam’s fully researched and manufactured doctor blades are in a class of their own – nothing comes close.

Esterlam’s precision-engineered synthetic blades are unique and should not be compared to other lower quality plastic blade materials available from non-specialist suppliers. The Esterlam product quality and specifications are significantly higher compared to other ‘plastic’ blades. That is why many leading organisations worldwide trust Esterlam synthetic blades to give them reliable high quality performance every time.

Old habits are often hard to break however printers and coaters must remain competitive. Esterlam blades provide printers with a real opportunity to improve in several areas of production including faster job turnarounds, less machine downtime, improving safety and less money spent on roller replacement. In some cases Esterlam blades can literally save a printer thousands of pounds a year. With many printers and coaters already using Esterlam blades, the biggest cost could be not trying them at all.

Depending on the process, Esterlam blades perform as well if not better than steel. Many companies in all areas of converting are constantly changing to the Esterlam blades due to the significant benefits offer. Of further interest is an FQC trial carried out by the FTA in the USA, which tested synthetic blades (Esterlam E600) against steel to measure the effect on dot gain. In summarising the report said that the Esterlam blade had caused less dot gain than steel both in narrow and wide web tests. A full copy of the report is available from the FTA or further details can be obtained from Esterlam.

This is fast becoming an out dated argument against change. If you do not accept the advances and changes being made, you won’t just stand still, you will fall behind every one else. Giant steps have been made in improving the quality of print, laminations and coatings. CONSISTENCY and REPEATABILITY are the new buzzwords as techniques and quality improves. Esterlam synthetic doctor and enclosure blades are the next major step forward in the evolution of the printing, coating and laminating industries because of the improved quality, consistency, production and safety benefits they offer.

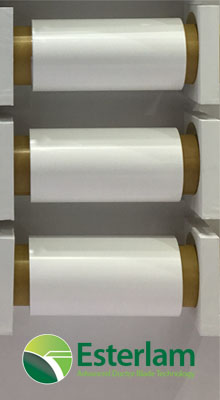

Esterlam blades are manufactured from tough yet less abrasive polyester based materials. These materials are significantly less abrasive than their steel counterparts and are used successfully on virtually every major make of machine with both chrome and ceramic rollers.

Customers using chrome rollers have on occasions more than trebled the life of their rollers since converting from abrasive steel to the Esterlam synthetic Blades.

Customers using ceramic rollers say that problems with scoring and polish lines are a thing of the past since eliminating steel blades from their machines.

Magnetic coating is considered to be one of the most abrasive coating applications. The process uses mirror finished chrome rollers, which are very prone to damage. Many of the worlds leading companies in this field almost exclusively use Esterlam synthetic blades because they significantly improve the life of the rollers.

Many OEM’s now recognise the benefits of Esterlam blades and offer them as a blade option on their presses. However there will always be some that remain traditional in their thinking or have financial interests in steel blade product sales. The only way people can make an informed choice is to try Esterlam blades for themselves. That is why Esterlam will supply a free sample plus give technical support to ensure each and every customer gains maximum benefit from the Esterlam blades.

This is no longer the case. The growing trend is towards the use of Esterlam synthetic doctor blade products because of the significant production and safety benefits they offer.

Esterlam’s customer portfolio makes very impressive reading and is growing every day. A few of the major companies using our blades include:- 3M, Tetra Pak, Rexam, Smurfit, BASF, MacTac, Avery, DuPont, ICI, Alusuisse Algroup, Sony, Georgia Pacific, Kimberly Clarke, International Paper, Stone Container, SKC, Aquaflex, Winkler and Dunnibier, Polytype, Martin, Harris & Bruno, BMB, Tecasa, Steinemann etc.

Esterlam are now acknowledged as world leaders in synthetic doctor blade technology. Esterlam have achieved this with the support of the network of technical agents we have worldwide and also by working closely with OEM’s and industry technical bodies.

Our own experiences plus industry news and technological advancements are updated on a daily basis and have resulted in a unique database of information which enables us give the most up to date technical advice and assistance to all of our customers.

Continuity of supply is also essential to any production facility. That is why Esterlam ensure all orders are promptly dispatched via recognised carriers world-wide, guaranteeing our customer’s peace of mind that their presses can continue to run successfully with Esterlam synthetic doctor blades.